Next-Gen Battery Technology Breakthroughs Explained

Introduction: The Power Bottleneck and the Quest for a Better Battery

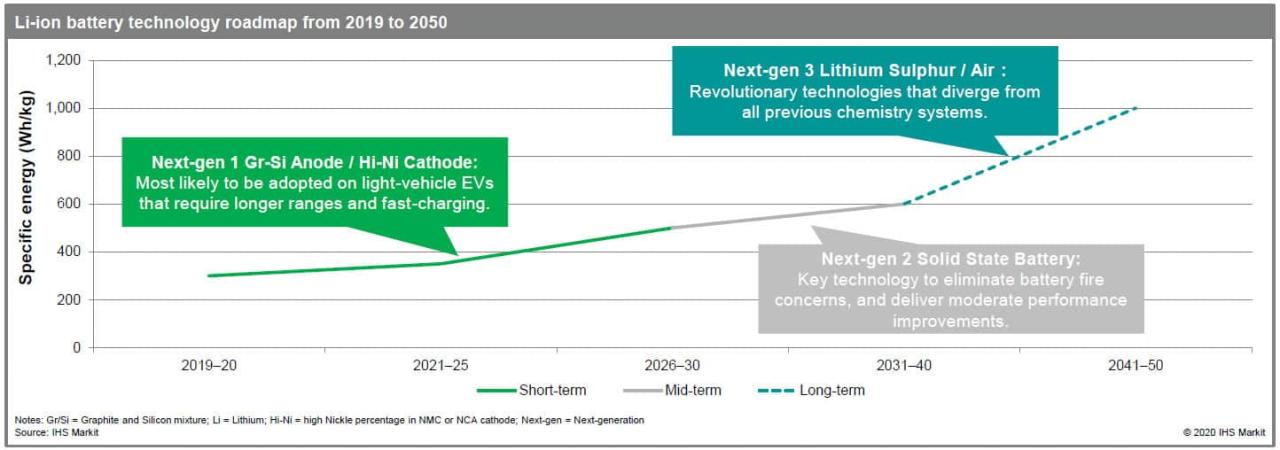

In an era defined by a global push towards electrification and renewable energy, a single technological bottleneck threatens to slow our progress: the humble battery. From the smartphone in your pocket to the electric vehicle (EV) in your garage and the vast power grids that sustain our cities, our modern world is utterly dependent on energy storage. For decades, the lithium-ion battery has been the undisputed champion, undergoing steady but incremental improvements. However, we are now approaching its theoretical limits. The demands for longer range, faster charging, enhanced safety, and greater sustainability are pushing scientists and engineers beyond the boundaries of conventional lithium-ion technology. We are standing at the precipice of a new energy storage revolution, driven by a wave of next-generation battery technologies that promise to redefine our relationship with power. This comprehensive guide delves deep into the science, the key players, and the real-world implications of these groundbreaking advancements that are poised to power the future.

A. The Limitations of Conventional Lithium-Ion Batteries

To appreciate the quantum leap that next-gen batteries represent, we must first understand why our current technology is failing to meet future demands. The standard lithium-ion battery has served us well, but it is plagued by fundamental constraints.

A. The Energy Density Ceiling: Energy density is the amount of energy a battery can store in a given volume or mass. Despite improvements, lithium-ion batteries are hitting a physical ceiling. This directly limits how long your phone can last on a charge and, more critically, how far an electric vehicle can travel before needing a recharge. The quest for higher energy density is the primary driver of battery innovation.

B. Charging Speed and Degradation: Fast charging generates intense heat, which accelerates the degradation of the battery’s internal components, particularly the liquid electrolyte and the anode. This leads to a reduction in overall capacity and lifespan over time. The fear of damaging the battery is a major psychological and practical barrier to EV adoption.

C. Thermal Runaway and Safety Concerns: Lithium-ion batteries contain a flammable liquid electrolyte. If the battery is damaged, overcharged, or has an internal short circuit, it can enter a state called “thermal runaway”—an uncontrollable, self-heating cycle that can lead to fires or explosions. This risk necessitates complex and expensive battery management systems.

D. Supply Chain and Ethical Issues: The key components of lithium-ion batteries, such as lithium, cobalt, and nickel, are finite resources. Their mining often has significant environmental impacts and, in the case of cobalt, is linked to serious ethical concerns regarding labor practices in the Democratic Republic of Congo. This creates a volatile and geopolitically sensitive supply chain.

E. Cost and Sustainability: While costs have fallen dramatically, the price of raw materials remains a significant portion of the total cost of an EV battery. Furthermore, recycling lithium-ion batteries is a complex and not yet universally economical process, leading to a growing electronic waste problem.

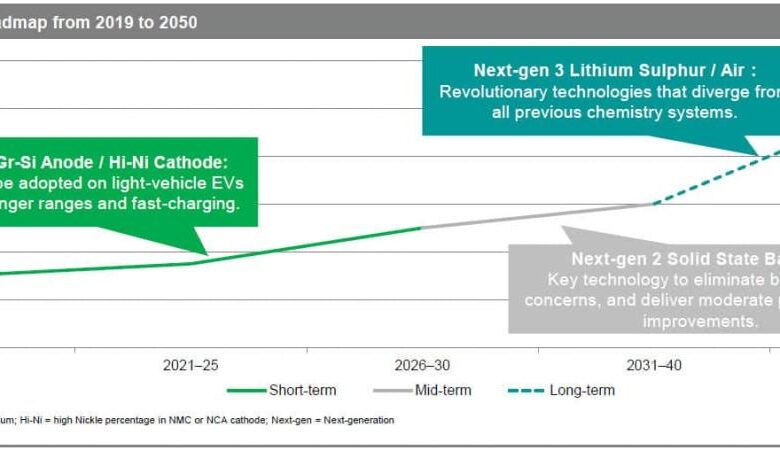

B. The Contenders: A Deep Dive into Next-Generation Chemistries

The global research community is pursuing several promising pathways to overcome these limitations. Here are the most prominent next-generation battery technologies.

B.1. Solid-State Batteries: The Holy Grail

Solid-state batteries represent the most anticipated evolution in energy storage. They replace the flammable liquid electrolyte found in conventional lithium-ion batteries with a solid, ceramic, or glass electrolyte.

A. Fundamental Architecture and How It Works: The core principle remains the same—lithium ions move from the anode to the cathode during discharge and back when charging. The revolutionary change is the medium through which they travel. The solid electrolyte is not only non-flammable but also enables the use of a pure lithium metal anode, often called the “dream anode.”

B. The Immense Advantages:

* Radically Improved Safety: The elimination of flammable liquid electrolyte virtually eliminates the risk of fire, making batteries inherently safer.

* Higher Energy Density: The lithium metal anode can store significantly more energy than the graphite anodes used today, potentially doubling the energy density. This could lead to EVs with 600-800 miles of range or smartphones that last for days.

* Faster Charging Times: Solid electrolytes can potentially allow for much faster ion movement, enabling ultra-rapid charging, potentially replenishing an EV battery in just 10-15 minutes.

* Longer Lifespan: With reduced side reactions and no liquid to decompose, solid-state batteries could endure many more charge cycles before significant degradation.

C. The Formidable Challenges:

* Manufacturing Complexity and Cost: Producing solid electrolytes with perfect consistency and integrating them into cells at scale is incredibly difficult and expensive with current technology.

* Interface Issues: The point where the solid electrolyte meets the solid electrode can create high resistance, impeding ion flow and reducing performance.

* Dendrite Suppression: While solid electrolytes are better at suppressing the growth of lithium dendrites (metallic filaments that can cause short circuits), the problem is not entirely solved, especially with pure lithium anodes.

D. Key Players and Timeline: Companies like QuantumScape (backed by Volkswagen and Bill Gates), Solid Power (partnered with Ford and BMW), and Toyota are leading the charge. While prototypes exist, mass production for consumer EVs is generally expected in the latter half of this decade.

B.2. Lithium-Sulfur (Li-S) Batteries: The Lightweight Champion

Lithium-sulfur technology takes a different approach, leveraging a chemistry that promises to be much lighter and potentially cheaper than lithium-ion.

A. Fundamental Architecture and How It Works: Li-S batteries replace the heavy, metal-based cathode (containing cobalt or nickel) with a sulfur-based cathode. Sulfur is abundant, cheap, and lightweight. The anode is typically lithium metal.

B. The Immense Advantages:

* Exceptional Theoretical Energy Density: Li-S batteries have a theoretical energy density several times higher than that of lithium-ion. This makes them ideal for applications where weight is critical, such as aviation (e.g., electric airplanes), drones, and long-haul trucking.

* Lower Cost and Abundant Materials: Sulfur is a common industrial byproduct, making it far less expensive and more abundant than cobalt and nickel.

* Improved Environmental Profile: The use of non-toxic sulfur is a significant environmental advantage over mining heavy metals.

C. The Formidable Challenges:

* The Polysulfide Shuttle: This is the primary technical hurdle. During cycling, intermediate compounds called polysulfides dissolve and shuttle between the electrodes, causing rapid capacity fade and short cycle life.

* Poor Conductivity: Sulfur is not naturally conductive, requiring complex composite cathode designs to function effectively.

* Volume Expansion: The sulfur cathode expands and contracts significantly during charging and discharging, which can mechanically degrade the battery structure over time.

D. Key Players and Timeline: Companies like Oxis Energy and Sion Power have been pioneers. NASA and various aerospace companies are heavily invested in Li-S research for aviation and space applications. Widespread commercial use is still likely several years away.

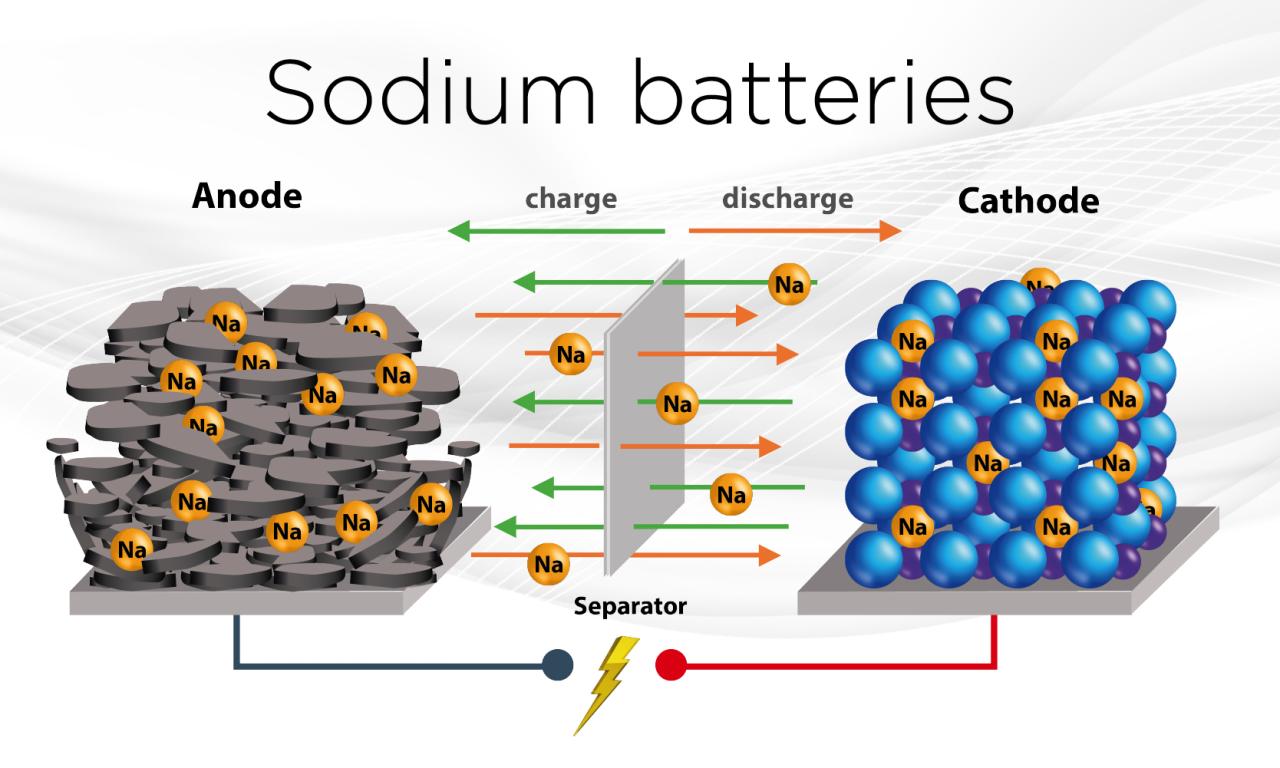

B.3. Sodium-Ion Batteries: The Sustainable and Scalable Alternative

Sodium-ion batteries are generating immense excitement not for outperforming lithium-ion in energy density, but for offering a compelling combination of cost, sustainability, and safety.

A. Fundamental Architecture and How It Works: As the name implies, these batteries replace lithium ions with sodium ions. Their fundamental working principle is very similar to lithium-ion, which allows for the adaptation of existing manufacturing equipment.

B. The Immense Advantages:

* Abundance and Low Cost: Sodium is one of the most abundant elements on Earth (found in seawater and table salt), making it incredibly cheap and freeing the technology from resource constraints.

* Enhanced Safety: Sodium-ion batteries are generally more stable and less prone to thermal runaway than lithium-ion.

* No Cold Weather Performance Dip: They can perform better than lithium-ion in colder temperatures, where lithium-ion efficiency drops significantly.

* Potential to Use Aluminum for the Anode: Sodium does not alloy with aluminum, allowing for the use of cheaper aluminum foil for the anode current collector instead of more expensive copper.

C. The Formidable Challenges:

* Lower Energy Density: Sodium ions are larger and heavier than lithium ions, resulting in a lower overall energy density. This makes them less suitable for premium EVs but perfect for other applications.

* Early-Stage Development: The technology is younger than lithium-ion, meaning the supply chain for materials and the manufacturing processes are less mature.

D. Key Players and Timeline: Chinese giant CATL, the world’s largest battery manufacturer, has already begun production of sodium-ion batteries. Their primary use cases are initially for lower-range city EVs, electric two-wheelers, and, most importantly, stationary energy storage for solar and wind farms, where size and weight are less critical than cost and longevity.

C. Enabling Technologies and Architectural Innovations

Beyond new chemistries, innovations in battery architecture and supporting technologies are crucial for unlocking performance.

A. Silicon and Silicon-Dominant Anodes: Instead of replacing the entire battery, many companies are working to supercharge lithium-ion by replacing the graphite anode with a silicon-based one. Silicon can store about 10 times more lithium ions than graphite. The challenge is that silicon expands dramatically during charging, which can pulverize the anode. Companies like Sila Nanotechnologies and Group14 are creating advanced silicon composites that mitigate this expansion, offering a 20-40% increase in energy density as a drop-in solution for existing battery factories.

B. The Tesla 4680 Battery Cell: This is a prime example of architectural innovation. Tesla’s 4680 cell is not a new chemistry but a larger, tabless design that improves power output, reduces manufacturing costs, and increases energy density at the pack level by simplifying the battery module structure. It’s a testament to how form factor and manufacturing can be as revolutionary as the chemistry itself.

C. Advanced Battery Management Systems (BMS): The “brain” of a battery pack is becoming increasingly intelligent. Next-gen BMS uses machine learning to precisely monitor the health of each individual cell, optimize charging patterns to extend lifespan, and proactively identify potential failures, thereby enhancing both safety and performance.

D. The Real-World Impact: Transforming Industries

The successful commercialization of these technologies will have a cascading effect across the global economy.

A. Electric Vehicles (EVs): This is the most visible battleground. Next-gen batteries will finally deliver the “mass-market EV”: a vehicle with 500+ miles of range that charges in the time it takes to get a coffee, is safer, and is ultimately cheaper to produce than a gasoline car.

B. Aviation and Heavy Transport: The high energy density of lithium-sulfur and advanced solid-state batteries is the key to electrifying short-haul aviation and long-haul trucking, sectors that are currently beyond the reach of today’s lithium-ion batteries.

C. Grid-Scale Energy Storage: To transition to a renewable energy grid, we need to store solar energy for use at night and wind energy for when the air is still. Cheap, abundant, and long-lasting batteries like sodium-ion are perfect for building massive storage facilities that can power entire cities, making a fossil-fuel-free grid a reality.

D. Consumer Electronics: Imagine a laptop that runs for 48 hours on a single charge or a smartphone that you only need to charge once a week. Next-gen batteries will untether our devices from the wall outlet in a way we’ve never experienced.

Conclusion: An Electrified Future Powered by Innovation

The race to develop the next generation of batteries is more than a technical competition; it is a foundational endeavor that will underpin the sustainable, electrified economy of the 21st century. While the path from the laboratory to mass production is fraught with scientific and engineering challenges, the progress is undeniable. We are moving beyond the one-size-fits-all approach of conventional lithium-ion into a diversified future where different battery chemistries will power different applications, from the skies to the grid.

The companies and nations that lead in this battery innovation cycle will wield tremendous economic and strategic influence. For consumers, the outcome promises a world of cleaner transportation, more resilient energy networks, and truly ubiquitous portable power. The next generation of batteries is not just an incremental improvement; it is the key that will unlock a brighter, more efficient, and fully electrified future for all.